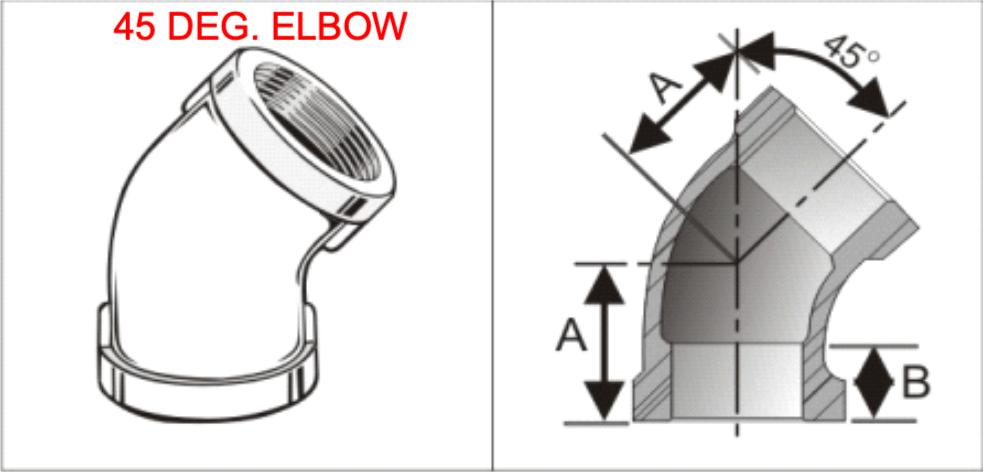

45 Degree Luj Tshib Cast Bronze Threaded Fitting

Yam khoom

| Yam khoom | Loj (inch) | Qhov ntev | Case Qty | Case tshwj xeeb | Qhov hnyav | ||||||||||||||||||

| Tus lej |

|

| A |

| B | Tswv | Sab hauv | Tswv | Sab hauv | (gram) | |||||||||||||

| l4501 ua | 1/8 | 0.42 ib | 0.26 | 600 | 5/ tas |

| 600 | 5/ tas |

| 34.2 ib | |||||||||||||

| l4502 ua | 1/4 | 0.56 ib | 0.35 Nws | 300 | 5/ tas |

| 300 | 5/ tas |

| 48.5 ib | |||||||||||||

| l4503 ua | 3/8 | 0.63 ib | 0.37 ib | 300 | 5/ tas |

| 300 | 5/ tas |

| 75 | |||||||||||||

| l4505 ua | 1/2 | 0.78 ib | 0.45 ib | 200 | 5/ tas |

| 200 | 5/ tas |

| 94 | |||||||||||||

| l4507 ua | 3/4 | 0.89 ib | 0.52 ib | 100 | 5/ tas |

| 100 | 5/ tas |

| 151.3 ib | |||||||||||||

| l4510 ua | 1 | 1.06 ib | 0.62 ib | 75 | 5/ tas |

| 75 | 5/ tas |

| 245.8 ib | |||||||||||||

| l4512 ua | 1-1/4 | 1.22 | 0.67 ib | 50 | 5/ tas |

| 50 | 5/ tas |

| 380.5 ib | |||||||||||||

| l4515 ua | 1-1/2 | 1.30 Nws | 0.70 ib | 40 | 5/ tas |

| 40 | 5/ tas |

| 499.2 ib | |||||||||||||

| l4520 ua | 2 | 1.45 Nws | 0.75 ib | 25 | 5/ tas |

| 25 | 5/ tas |

| 691.6 ib | |||||||||||||

| l4525 ua | 2-1/2 | 1.95 ib | 0.92 ib | 12 | 1/ tas |

| 12 | 1/ tas |

| 1420 | |||||||||||||

| l4530 ua | 3 | 2.17 | 0.98 ib | 8 | 1/ tas |

| 8 | 1/ tas |

| 2185 ib | |||||||||||||

| l4540 ua | 4 | 2.61 ib | 1.38 ib | 4 | 1/ tas |

| 4 | 1/ tas |

| ib 3670 | |||||||||||||

| 1.Technical: Casting | 6. Khoom siv: ASTM B62, UNS Alloy C83600; ASTM B824 C89633 |

| 2. Hom: "P" | 7.Fitting Dimensions: ASEM B16.15 Class125 |

| 3.Product Cap.: 50Ton / Mon | 8.Threads Standard: NPT ua raws li ASME B1.20.1 |

| 4. Keeb kwm: Thaib teb | 9.Elongation: 20% Tsawg |

| 5.Daim ntawv thov: Jointing dej yeeb nkab | 10.Tensile zog: 20.0kg / mm (yam tsawg kawg nkaus) |

| 11.Package: Exporting Stardard, Master Carton nrog cov thawv sab hauv Master Cartons: 5 txheej corrugated ntawv | |

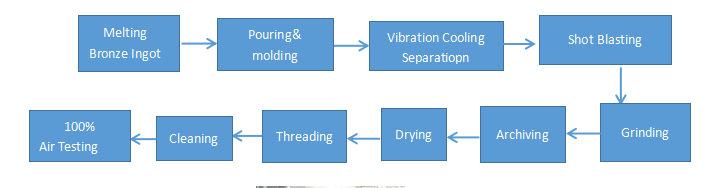

Txheej txheem ntau lawm

Kev Tswj Xyuas Zoo

Peb muaj tag nrho cov kev tswj xyuas zoo.

| Txhua daim fittings yuav tsum raug soj ntsuam raws li nruj SOP txawm li cas los ntawm thawj cov khoom raw nkag mus rau cov khoom ua tiav rau cov khoom tiav uas yog 100% dej kuaj tsim nyog ua ntej lawv nkag mus rau hauv peb lub tsev rau khoom. | 1.Raw Material checking, khaws cov khoom tuaj tsim nyog |

| 2. Moulding 1).Kuaj xyuas lub tem.ntawm molten hlau.2. Tshuaj muaj pes tsawg leeg | |

| 3.Rotary txias: Tom qab Casting, zoo li kev soj ntsuam | |

| 4. Sib tsoo Cov tsos mob kuaj | |

| 5.Threading In-process checking tsos thiab threads los ntawm Gages. | |

| 6. 100% Dej Siab Tested, xyuas kom tsis muaj qhov to | |

| 7.Package: QC kuaj xyuas yog tias cov khoom ntim khoom yog tib yam nrog kev txiav txim |

| Hom | Cu% | Zn% | Pb% | Sn% |

| c83600 ua | 84.6-85.5 Nws | 4.7-5.3 | 4.6-5.2 | 4.7 ~ 5.1 |

Peb Slogan

Khaws txhua cov yeeb nkab haum uas peb cov neeg siv khoom tau txais yog tsim nyog.

FAQ

Q: Koj puas yog lub Hoobkas lossis tuam txhab lag luam?

A: Peb yog lub Hoobkas nrog +30 xyoo keeb kwm nyob rau hauv casting teb.

Q: Cov nqe lus them nqi dab tsi koj txhawb nqa?

A: TTor L / C.30% them ua ntej, thiab 70% tshuav nyiaj li cas

them ua ntej khoom xa tuaj.

Q: Koj lub sijhawm xa khoom ntev npaum li cas?

A: 35 hnub tom qab tau txais cov nyiaj them ua ntej.

Q: Nws puas tuaj yeem tau txais cov qauv ntawm koj lub Hoobkas?

A: Yog.kuaj dawb yuav muab.

Q: Muaj pes tsawg xyoo cov khoom lav?

A: Yam tsawg kawg 1 xyoos.